Nerve/skin/muscle grease-gap and other preparations

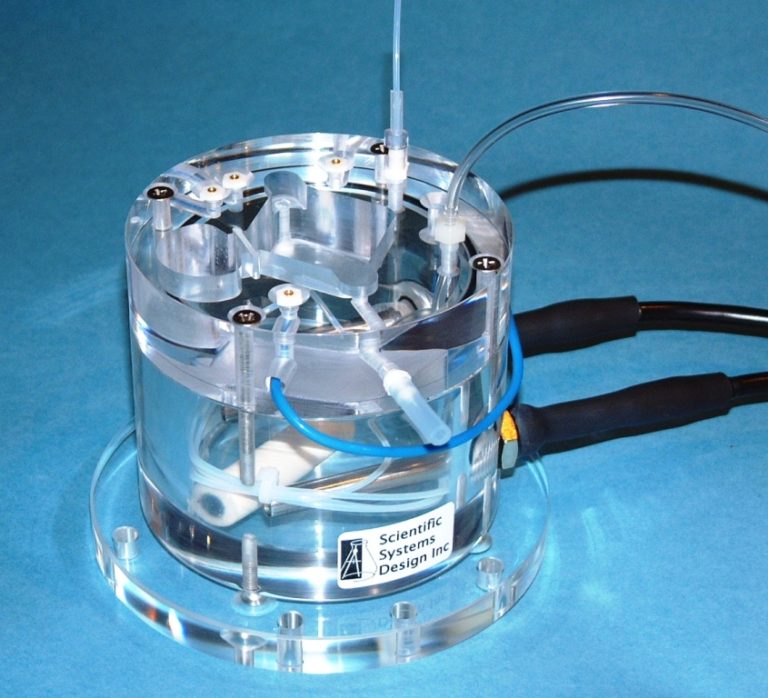

Description

This chamber consists of two main cells, one is a large diamond-shape for containing the preparation and the other is a smaller oval-shaped cell where nerve ends are arranged for making electrical recordings. These two cells are separated by a removable acrylic partition. The bottom edge of this partition can be fashioned to leave a small arch through which nerve bundles can pass through for grease gap recording methods. The larger cell is normally pre-filled with an inert self-curing silicone rubber substrate to allow various types of preparations to be pinned in place. The smaller oval cell is supplied with a small pedestal on which a small pane of mirrored glass is used as a substrate to separate nerves from a nerve bundle with the aid of a dissecting microscope arranged over the cell. Hook-wire electrodes are arranged from nearby 1mm connectors for recording and stimulating functions as are ground electrodes for both nerve and preparation areas. Perfusion fluid flows into the chamber via a Teflon tube which first spirals in the base of the chamber. This base contains temperature control heating and sensor elements connected to a separately available proportional temperature controller for pharmacology only experiments PTC04 or for low noise electrophysiology use the PTC03. The warmed perfusion solution in the spiral then flows over the preparation in the diamond-shaped area and exits at the opposite end where it can be sucked off from a tube fitting. In addition there is provision for the diamond-shaped cell to maintain high humidity and control the gaseous environment for experimental anoxia or other gas combinations.

Features

- Isolated organ, skin, nerve and muscle preparations

- Preparations maintained for many hours in flowing incubating media

- Large diamond-shaped flow cell for maintaining preparations on a custom substrate

- Grease-gap across a removable acrylic partition

- Temperature controlled base heats incoming media flowing across preparation

- Humidity and gas environment can be controlled within diamond-shaped flow cell

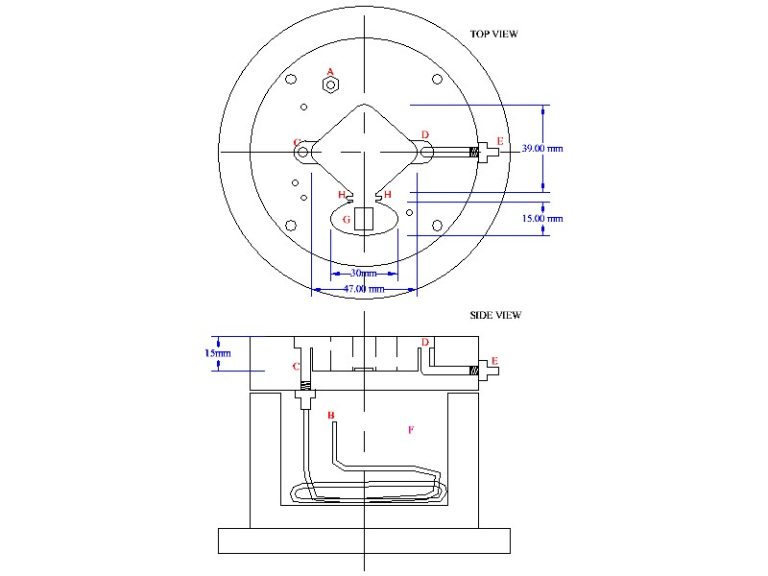

Schematic

Parts description

Feed solution enters through a plastic screw fitting A located on the top surface that connects to approx. 30 inches of PTFE tubing to point B (connection not shown). The PTFE tubing spirals in the chamber base F which contains distilled water heated by a heater cartridge and connected to a temperature controller (PTC03). Warmed feed solution enters plastic fitting at C raised 5mm above main diamond shaped trough into which appropriate depth of Sylgard® or other silicone substrate will be set (by the end user). The Sylgard will not spill into the in / out ports as they are raised 5mm above the base. Solution is made to wick across the diamond Sylgard base with filter paper and reaches exit port D and then on to an exit plastic screw fitting E connected to a house waste vacuum line. Nerves are routed through a barrier located into grooves H-H (not shown) with a hole in it at the bottom. The nerve bundles are arranged on a raised mirror located in an oval area G and wire electrodes arranged from pin sockets on the surface.